Feedstock

Feedstock is one of the most challenging parts of building and operating an anaerobic digestion system. Feedstock quantity and quality MUST be established and long-term contracts MUST be secured early in the project. This is because anaerobic digestion systems MUST be designed around available feedstock, and not the other way around.

There are three types of feedstock that can go into an anaerobic digestion system. These are:

- Byproducts produced by a farming operation: such as manure, bedding, feed waste, crop residue and culls, and runoff from silos.

- Off-farm source materials: such as products and byproducts from food processing plants, source-separated organics, grease trap residuals, and other non-agricultural source materials.

- Energy crops: such as corn silage, forages or whole plant sugar beets grown for the express purpose of producing energy.

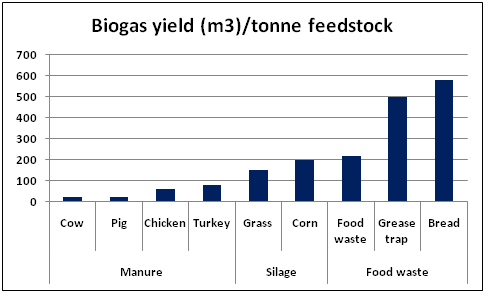

Of these feedstock, perhaps the most important (and challenging) is off-farm feedstock because it is essential to the economic viability of almost all on-farm anaerobic digestion systems in North America. The reason for this is that off-farm feedstock contains the most energy and thus produces the most biogas. For example, while a dairy herd of 100 milking cows and replacements can produce 15 - 20kW, adding 25% good quality off-farm feedstocks (such as grease trap waste or dough) will triple the electrical output to 60 - 75kW.

Important feedstock considerations

- Quantity: the quantity of feedstock must be constant and should not fluctuate much through the life of the project. Anaerobic Digestion systems are optimized for a given flow rate and cannot take too much variation without decline in efficiency or problematic operation.

- Quality: while the quality of on-farm manure is relatively constant, the same is not true for off-farm feedstock. Constant feedstock supply from a single or very few point sources is generally preferable to feedstock from various waste collectors, as quality is more predictable. Nevertheless, great care must be taken to minimize contaminants in all off-farm feedstock (plastic, metal, chemical, antibiotics, etc).

- Volume: anaerobic digestion systems require a certain volume of feedstock to be economically viable. While this will change with advancements in technology and energy contracts from BC Hydro, a general rule of thumb is that a minimum of 100 – 150 milking cows (equivalent to 5,000 tons manure/year) or 3,000 tons/year organic material is required.

Revenue

- Gate fees: off-farm feedstocks are accepted for a gate fee (sometimes referred to as a tipping fee). The revenue from these fees are often instrumental in making an anaerobic digestion systems economically viable. As such, it is vitally important that off-farm feedstock long-term contractual agreements are secured before any construction begins.

- Biogas output: different feedstocks produce different volumes of biogas. As such, and depending on quantity and quality, mixing of off-farm feedstocks with manure may double or even triple biogas production. For example, off-farm feedstocks such as grease trap and bread waste will have a much greater impact on biogas production that grass or corn silage.

Calculations

Currently, there is very little, accurate, publically available information on the biogas potential of off-farm feedstock. Furthermore, any information that does exist is very site specific and may not hold true for identical feedstock in other locations (for example, grease trap waste biogas potential in location A, due to solids content, may be very different from grease trap waste biogas potential in location B).

As such, before building an anaerobic digestion system, project managers/owners must undertake extensive feedstock sampling and analysis to determine the true biogas potential of the feedstock they have access to.